This allows the device to be wedged snugly between two components in order to hold them in place. It is common for cotter pins to have a slightly larger body in countries such as the United Kingdom. Although they all perform the same basic function, they differ depending on the type of machinery involved and the size of the components being connected. It is even possible to find a cotter pin that is circular or rounded called a circle cotter. R-clip pins and bowtie pins are two types of cotter pins that are used in different settings and are the most commonly used. The cotter pin is available in many different types today. $10.97 Buy on Amazon Types of Cotter pins When the cotter pin is used this way, it is less likely that the bolt might also emerge if the cotter pin wiggles out. In spite of people’s impression that cotter pins are best twisted together, these simple fasteners offer the greatest protection against loosening when twisted apart. After twisting the prongs on the cotter pin, turn them outward and away from each other. The cotter pin can be used by simply putting it through the hole of the bolt. During installation, you need pliers, a castle nut, a drilled bolt, and pliers to make these fasteners. A variety of applications can be performed with it. Cotter pins cannot be inserted without a hole.

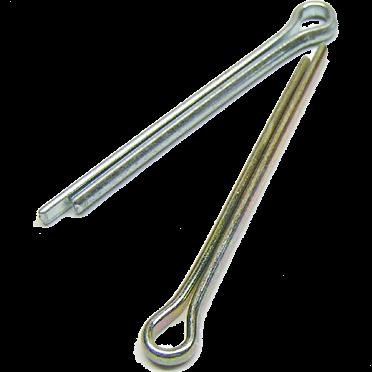

Cotter pins can only be inserted into bolts that have holes. The use of a cotter pin is not supported by all bolts. A cotter pin prevents a bolt from being removed from the hole in which it is inserted. Although cotter pins are all metal fasteners, they come in a variety of types.Ĭotter pins or split pins work on locking mechanisms. Typically, cotter pins can be removed by pulling them out. Using a cotter pin, you can secure a component in a hole.During compression, friction is generated, which prevents the pin from loosening and ensures smooth operation. Tapered refers to the fact that the pins compress as they enter the holes.The pins are wedge-shaped or tapered and driven into the holes. Axial motion along the shaft is usually stopped with these pins.Save my name, email, and website in this browser for the next time I comment. This type of cotter has been largely replaced by splines and square shafts. This is used to draw the cotter into the hole and retain it in position. Cotters might have a threaded shaft protruding from the narrower end of the taper. Conventionally, it’s been used to attach cranks onto shafts (say, for example, on bicycles and steam engines). This brings us to the traditional cotter pin, which is a wedge that’s driven or drawn into a hole. Key rings are a common application for this type of fastener although they may also be used to retain pins and shafts. Essentially, it’s a wire loop that extends beyond 360 degrees allowing it to be threaded through a hole. Split ring: These components are also called a circle cotter or cotter ring. A finger can be inserted through the ring at the head to pull the pin out of the hole. The straight section may be pushed through a hole in a shaft, while the curved section clips around the outside of the shaft, retaining the pin in place. They’re sprung pins with a straight section that bends to form a ring at the head, with a curved section offset from the straight pin. R-clips or R-pins: These pins are sometimes referred to as hairpin cotters. The bent end is formed into an enlarged end and the double end can be bent outwards to prevent the pin being removed. The pins are usually manufactured from a half-circular profile so that the two ends together form a circle, which fits into the hole. Split pins: Often called cotter pins, split pins are bent in half so that both ends may be inserted through the same hole. Here are a few of the different types of fasteners that are also considered cotter pins: However, the term “cotter pin” is also sometimes referred to as a split pin, an R-clip, or a circle cotter.

The tapered nature of this pin means that it’s compressed as it is driven into the hole, causing friction, which prevents it from working loose.

They’re either a wedge or tapered pin that’s driven into a hole. A selection of fasteners that are referred to as cotter pins (from left to right): Traditional tapered cotter as used on a steam engine, a cotter with a threaded section, as used on a bicycle crank, a split pin, an R-clip, and a split ring.Ĭotter pins are typically used to prevent axial movement along a shaft.

0 kommentar(er)

0 kommentar(er)